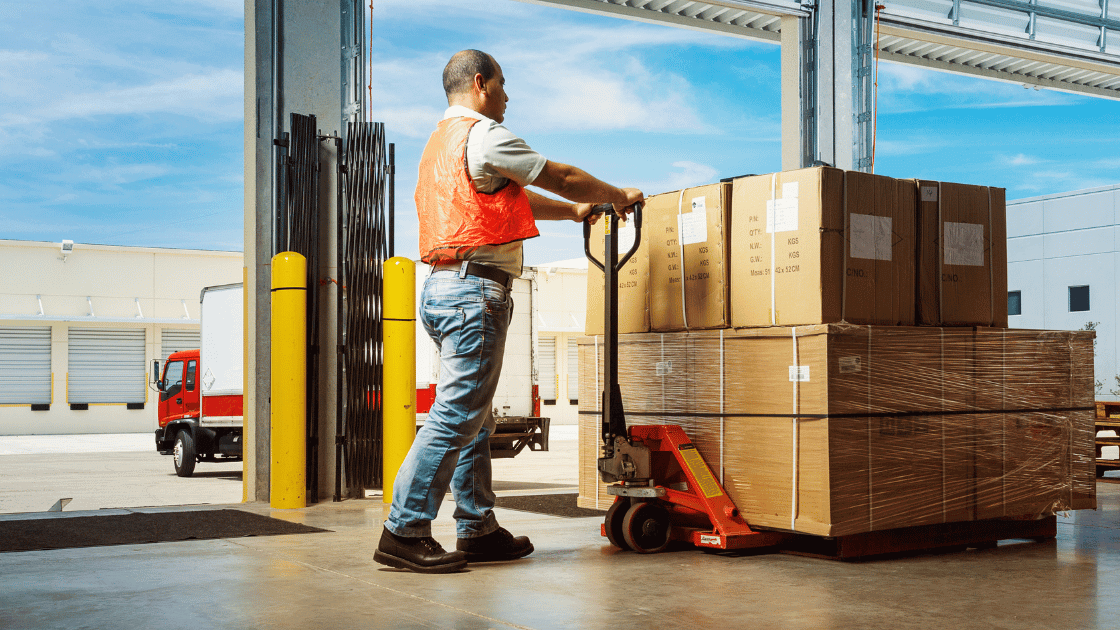

Regular maintenance of a hand-operated pallet truck prevents breakdowns, extends service life, and ensures safe warehouse operations.

A proactive preventive maintenance routine for your hand operated pallet truck reduces unplanned downtime, safeguards operators, and extends equipment life. By following simple daily inspections, weekly lubrication and oil checks, and a deeper monthly routine, ARAS Handling Equipment customers in Dubai can avoid costly repairs and minimize Hand Operated Pallet Truck troubleshooting calls while ensuring safe, efficient warehouse operations.

Why Preventive Maintenance Matters

Fact Snippet:

Regular preventive maintenance helps catch wear early, extend life, and reduce breakdowns because proactive checks stop small issues from escalating into major repairs. According to preventive maintenance practices, identifying wear early prevents costly breakdowns and improves equipment reliability.

Daily Pallet Truck Maintenance Checklist (Before Every Use)

Perform daily inspections before operating.

What to Check Daily

- Fork condition – Look for cracks or bends.

- Hydraulic leak test – Check the pump area for oil seepage.

- Wheels – Ensure free rotation and no debris.

- Handle & controls – Confirm smooth moving function.

- Load capacity label – Must be visible.

Weekly Maintenance Tasks

Once a week, tackle these upkeep activities:

- Grease Moving Parts

Follow a Hand Operated Pallet Truck lubrication guide: apply grease to grease zerks on axles, wheels, and pivot joints. Proper lubrication reduces friction and prevents premature wear on your manual pallet jack. - Check Hydraulic Oil Level

Verify fluid level through the sight glass or dipstick. Top up every six months and replace annually to maintain proper viscosity—critical in Dubai’s heat. - Fork Alignment

Measure fork tine heights at full lift. Uneven forks can damage Hand Operated Pallet Trucks and strain the hydraulic pump; realign push‑rods if the difference exceeds 5 mm.

Monthly Maintenance Routine

Dedicate time each month for these comprehensive checks:

- Deep Cleaning

Wipe down the entire jack with a mild cleaner. A clean frame and forks make it easier to spot hairline cracks or corrosion on low profile pallet jacks. - Inspect Bearings and Rollers

Remove wheels to check bearings for play or noise. Replace any bearing that feels rough or exhibits side‑to‑side movement to prevent wheel seizure and downtime. - Operational Load Test

Load the jack to its rated capacity and move it over a flat surface. Listen for unusual noises and ensure smooth pump action under load; hesitation often indicates internal issues. - Frame and Push‑Rod Check

Examine push‑rods beneath forks for proper adjustment. Misaligned rods cause forks to sit unevenly under pallets, leading to Hand Operated Pallet Truck troubleshooting problems.

Safety Considerations

- Adhere to Load Capacity: Never exceed the jack’s rated load; overloading is a leading cause of hydraulic failure and operator injury

- Proper Operation: Train staff “how to operate a manual pallet jack”—always push rather than pull when possible, to reduce strain and improve control

- Record Keeping: Log all inspections and maintenance tasks. Detailed records support audit compliance and help schedule timely servicing.

When to Call ARAS Handling Equipment

If daily, weekly, or monthly checks reveal persistent hydraulic leaks, bent forks, or worn bearings, schedule a professional service with ARAS Handling Equipment in Dubai. Our certified technicians specialize in pump trucks and manual material handling equipment, ensuring your fleet remains safe, compliant, and ready for the next shift.

By systematically following this preventive maintenance checklist for your hand operated pallet truck, you’ll protect your team, minimize unexpected downtime, and extend the life of your most critical warehouse asset. For expert advice, genuine spare parts, or on‑site servicing in Dubai, contact ARAS Handling Equipment today—your partner in material‑handling excellence.