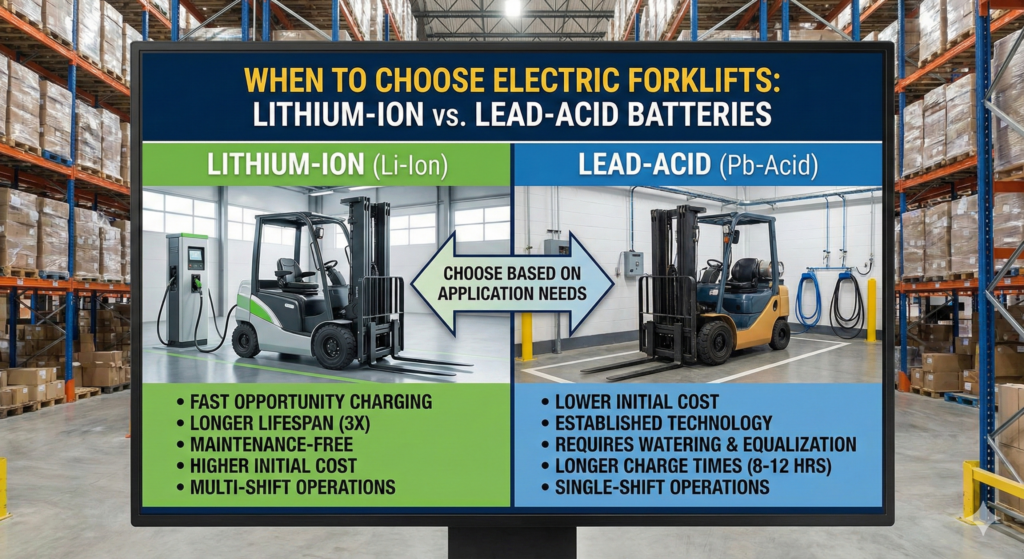

Battery Technology Overview: Lithium-Ion vs. Lead-Acid

Electric forklifts rely heavily on the performance and reliability of their battery systems. For years, lead-acid batteries have been the industry standard. But lithium-ion batteries have quickly emerged as a game-changing alternative for operations that demand higher uptime, faster charging, and lower long-term maintenance.

Lead-Acid Batteries

Lead-acid technology is familiar, widely available, and typically cheaper upfront. However, it comes with operational limitations:

- Gradual power decline as the battery discharges

- Long charge and cooldown times

- Required maintenance (watering, equalization, cleaning)

- Elevated safety requirements due to off-gassing

Lithium-Ion Batteries

Lithium-ion batteries deliver higher efficiency and are built for continuous, high-demand use. Advantages include:

- Consistent power output throughout the shift

- Short, flexible charging windows

- Zero routine maintenance

- Sealed construction with no emissions

If your operation depends on speed, predictability, and safety, lithium-ion provides noticeable performance improvements over traditional lead-acid systems.

Charging Logistics: The Operational Turning Point

Charging patterns are often the biggest differentiator between lead-acid and lithium-ion batteries—and the biggest reason businesses choose to switch.

Lead-Acid Charging Requirements

Lead-acid batteries must follow a strict, time-consuming charging cycle:

- 8 hours to fully charge

- 8 hours to cool

- Dedicated charging rooms for ventilation

- Battery swaps for multi-shift environments

- Strict charge schedules to avoid damaging the battery

This structure works reasonably well for single-shift operations, but becomes expensive and inefficient in multi-shift or high-output environments.

Lithium-Ion Charging Advantages

Lithium-ion batteries eliminate nearly all of the restrictions above:

- Fast charging — often full in 1–2 hours

- No cooldown period

- No battery swaps needed

- Safe to charge anywhere on the floor

- Supports opportunity charging (during breaks, shift changes, or loading lull periods)

This flexibility dramatically reduces downtime and fleet size requirements, making lithium-ion a strong choice for businesses aiming to keep vehicles moving as much as possible.

Productivity Gains: Going Beyond Charging Speed

Lithium-ion forklift batteries do more than charge quickly—they fundamentally improve daily workflow.

Eliminating Battery Swaps

Lead-acid forklifts often require an extra battery per truck and consistent labor for swapping. Each change can take 15–20 minutes, disrupt workflow, and increase safety risks.

With lithium-ion, the same battery stays in the truck. Operators simply plug in during breaks, and the truck is ready again with minimal interruption.

Consistent Power Output

As lead-acid batteries discharge, voltage drops. That results in:

- Slower lift speeds

- Reduced acceleration

- Less responsive hydraulics

Lithium-ion batteries hold steady power until nearly empty. Operators experience:

- Faster cycle times

- More predictable handling

- Fewer interruptions due to sluggish performance

Better Performance in Harsh Environments

Lithium-ion excels in:

- Cold storage, where lead-acid loses capacity

- High-intensity applications requiring sustained power

- Automated systems (AGVs/AMRs) that depend on precise power levels

If maximizing throughput is a priority, lithium-ion often delivers measurable improvements.

Maintenance & Lifecycle Differences

Lead-Acid Maintenance Needs

To perform reliably, lead-acid batteries must be:

- Watered regularly

- Equalized on schedule

- Cleaned to prevent corrosion

- Stored and charged in ventilated areas

- Carefully monitored for heat and wear

This creates ongoing labor, training, and safety considerations.

Lithium-Ion Maintenance: Minimal

Lithium-ion batteries are sealed and require:

- No watering

- No equalization

- No specialized ventilation

- No corrosion cleaning

They also include smart Battery Management Systems (BMS) that monitor health, temperature, and charging to extend lifespan and reduce risk.

Lifecycle Expectation

- Lead-acid: ~1,000–1,500 cycles

- Lithium-ion: ~2,500–4,000+ cycles

Over the life of the equipment, lithium-ion typically lasts 2–3× as long, reducing replacement frequency and long-term cost.

Total Cost of Ownership & ROI: When Lithium-Ion Makes Financial Sense

Although lithium-ion batteries require a higher upfront investment, the long-term savings can be dramatic.

Where Lithium-Ion Provides Clear ROI

- Multi-Shift or 24/7 Operations

No need for multiple batteries per truck, extra chargers, or swap labor. - Labor Efficiency

Eliminating battery changes and maintenance tasks reduces ongoing labor costs. - Energy Costs

Lithium-ion is significantly more energy efficient, lowering electricity usage. - Space Utilization

Removing battery rooms frees valuable warehouse square footage. - Longer Battery Life

Fewer battery replacements means fewer capital purchases over time.

When Lead-Acid May Still Be the Right Choice

- Single-shift operations with long downtime periods

- Tight budgets where lowest upfront cost matters more than long-term savings

- Existing infrastructure already optimized for lead-acid

Practical Scenarios to Help You Decide

✓ Choose Lithium-Ion If:

- You run two or more shifts

- Forklift uptime directly affects productivity

- You want to eliminate battery swaps

- You’re operating in cold storage

- You want lower long-term costs and less maintenance

- You’re tight on space and want to remove your battery room

✓ Choose Lead-Acid If:

- You operate only one shift per day

- Trucks have long idle periods for charging

- You’re working with a limited upfront budget

- Your facility already has a well-managed lead-acid support system

Conclusion: Which Battery Type Is Right for You?

Lithium-ion forklift batteries offer substantial advantages in flexibility, uptime, safety, and total cost of ownership—especially for operations with high utilization or multiple daily shifts. Their ability to charge quickly, maintain consistent power, and eliminate maintenance makes them an increasingly popular choice for modern material-handling environments.

Lead-acid batteries remain suitable for lower-intensity applications where budget constraints and existing infrastructure make them the practical choice.

Choosing the right battery comes down to your operational rhythm, throughput expectations, and long-term equipment strategy.