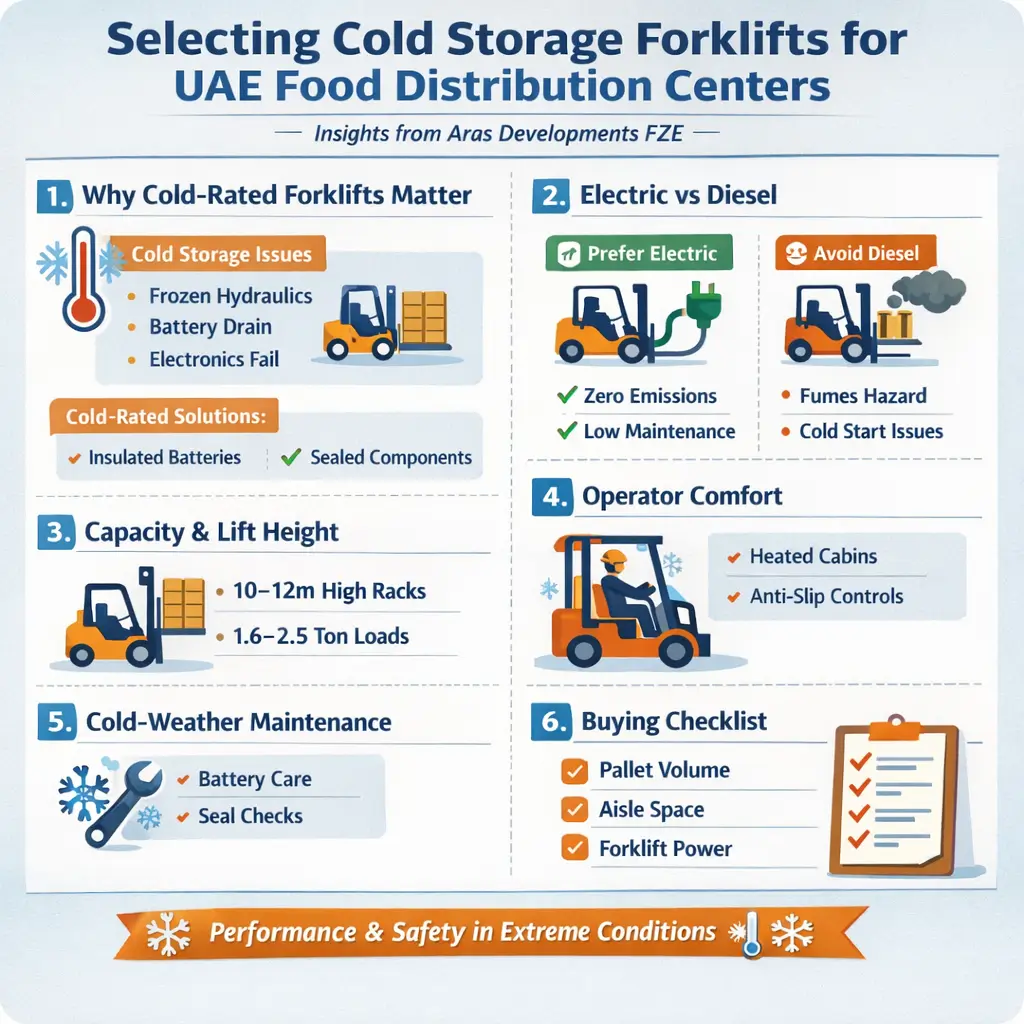

Operating cold storage facilities in the UAE presents material handling challenges that differ fundamentally from ambient warehouse environments. Food distributors, pharmaceutical companies, and cold chain logistics providers require forklifts engineered to perform reliably in extreme temperature conditions while maintaining operational efficiency and worker safety.

The selection process for cold storage material handling equipment demands careful consideration of environmental factors, operational requirements, and long-term performance characteristics specific to the UAE’s logistics infrastructure.

What Makes Cold Storage Forklift Different from Regular Warehouse Equipment?

Standard forklifts experience multiple failure points when deployed in cold storage environments. Cold Storage Forklift address these challenges through specialized engineering designed for temperature extremes between -25°C and +4°C.

Common Cold Storage Forklift Equipment Failures:

- Hydraulic fluids thicken at low temperatures, reducing lift speeds by up to 40%

- Lead-acid batteries lose 50% capacity at -20°C

- Electronic components face condensation damage during temperature transitions

- Seals and gaskets deteriorate from thermal cycling stress

- Standard lubricants become viscous, compromising mechanical performance

Cold Storage Forklift Engineering Solutions:

- Low-temperature viscosity hydraulic fluids maintain flow characteristics at freezing temperatures

- Sealed electrical compartments prevent moisture intrusion

- Enhanced battery insulation preserves optimal operating temperatures

- Reinforced seals withstand repeated thermal cycling

- Specialized gaskets resist cracking in subfreezing conditions

For UAE operations where ambient temperatures regularly exceed 40°C in summer months, equipment must transition repeatedly between extreme heat and subfreezing cold storage zones. This thermal cycling places extraordinary stress on components that standard equipment cannot withstand reliably.

Should You Choose Electric or Diesel Forklifts for Cold Storage Operations?

Electric forklifts dominate cold storage applications for compelling operational and safety reasons.

Why Electric Equipment Outperforms Combustion Engines:

- Zero exhaust emissions comply with food safety standards

- No water vapor production that creates dangerous ice buildup

- Precise control in confined cold storage aisles

- Lower maintenance requirements in controlled environments

- Reduced ventilation needs decrease cooling costs

Diesel Forklift Limitations in Cold Storage:

- Exhaust emissions contaminate food products and pharmaceuticals

- Water vapor from combustion freezes on floors and racking

- Increased air exchange requirements raise refrigeration costs

- Carbon monoxide safety concerns require expensive monitoring systems

- Poor cold-start performance in freezer environments

Lithium-Ion Battery Advantages:

- Maintain consistent voltage throughout discharge cycles

- Resist performance degradation at temperatures down to -25°C

- Built-in thermal management systems preserve battery temperature

- Eliminate watering maintenance requirements

- Deliver 30% more operational hours compared to lead-acid batteries

The absence of emissions becomes particularly significant in UAE cold storage facilities serving food distribution networks and pharmaceutical storage operations. Maintaining product integrity requires absolute control over storage atmospheres that electric equipment provides.

How Do You Determine the Right Load Capacity and Lift Height for Cold Storage?

Cold storage facilities maximize cubic space utilization through high-density racking configurations. UAE food distribution centers commonly implement vertical storage systems to minimize refrigerated footprint and associated energy consumption.

Typical UAE Cold Storage Specifications:

- Pallet racking heights: 10 to 12 meters

- Aisle widths for reach trucks: 2.7 to 3.0 meters

- VNA system aisle widths: 1.8 to 2.2 meters

- Standard pallet positions per square meter: 3 to 5, depending on configuration

- Load capacity requirements: 1.6 to 2.5 tons for food distribution

Electric Reach Truck Capabilities:

- Lift heights exceeding 11 meters

- Operation in aisles as narrow as 2.7 meters

- Load capacities between 1.5 and 2.5 tons

- Vertical reach capability maximizes storage density

- Precise load placement at height reduces product damage

VNA Forklift Advantages for Large Operations:

- Access loads at heights up to 14 meters

- Operate in aisles as narrow as 1.8 meters

- Increase pallet positions by 40% compared to standard configurations

- Require guided wire or rail guidance systems

- Deliver ROI through dramatic space efficiency gains

Each square meter of refrigerated space carries substantial capital and operating costs in the UAE market. Vertical storage optimization directly impacts facility economics, making equipment selection a strategic financial decision.

Also Read: Warehouse Operations in Cold Storage

Why Does Operator Comfort Matter in Cold Storage Productivity?

Cold storage environments impose physical strain on operators that directly affects productivity, safety, and labor retention.

Cold Exposure Impact on Operators:

- Extended exposure causes fatigue and reduces concentration

- Manual dexterity decreases by 20% in subfreezing temperatures

- Reaction times slow, increasing accident risk

- Worker turnover increases in facilities without proper equipment

- Productivity drops 15-25% without climate-controlled equipment

Heated Cabin Benefits:

- Maintain normal operator body temperature during full shifts

- Increase productivity by 20-30% in freezer environments

- Reduce worker compensation claims related to cold exposure

- Improve employee retention in cold storage positions

- Pay for themselves within the first operational year through productivity gains

Stand-On Reach Truck Applications:

- Ideal for mixed-temperature facilities

- Allow rapid mounting and dismounting

- Suitable for operations with frequent zone transitions

- Reduce operator fatigue from repeated cabin entry/exit

- Lower initial investment compared to enclosed cabins

Cold Storage Ergonomic Requirements:

- Larger control buttons accommodate insulated gloves

- Intuitive layouts minimize fine motor requirements

- Clear visibility systems compensate for reduced peripheral vision

- Anti-slip flooring prevents falls from ice accumulation

- Emergency heating systems protect operators during equipment failures

What Maintenance Do Cold Storage Forklift Need in the UAE Climate?

Cold Storage Forklifts require maintenance protocols adapted to thermal stress and condensation exposure unique to UAE operations.

Critical Maintenance Focus Areas:

- Door seals require monthly inspection to prevent moisture intrusion

- Electrical connections need a quarterly corrosion assessment

- Hydraulic lines demand frequent inspection for cold-weather cracking

- Battery terminals require anti-corrosion treatment every 90 days

- Wheels and bearings need low-temperature grease application

Thermal Cycling Challenges:

- Transition from 40°C ambient to -25°C freezer generates severe condensation

- Metal surfaces corrode 3x faster than standard warehouse environments

- Protective coatings require renewal every 6-12 months

- Sealed compartments need verification to confirm moisture barriers remain intact

- Gaskets and seals face accelerated degradation, requiring proactive replacement

Battery Maintenance Strategies:

- Opportunity charging minimizes battery temperature fluctuation

- Lithium-ion systems eliminate watering labor in cold environments

- Battery room temperature control preserves charge capacity

- Regular capacity testing identifies degradation before failures occur

- Proper charging protocols extend battery life by 30-40%

Preventive Maintenance ROI:

- Scheduled inspections prevent 70% of Cold Storage Forklift failures

- Proactive component replacement reduces downtime by 60%

- Proper maintenance extends equipment life by 3-5 years

- Regular service maintains resale value for future equipment upgrades

- Documented maintenance supports warranty claims and insurance requirements

How Do You Choose the Right Cold Storage Forklift for Your UAE Facility?

Choosing appropriate Cold Storage Forklifts begins with a comprehensive operational analysis aligned with facility requirements and product specifications.

Operational Analysis Requirements:

- Daily throughput volume: pallets moved per shift

- Peak activity periods and seasonal demand fluctuations

- Product turnover rates and inventory rotation cycles

- Shift patterns: single, double, or continuous operation

- Current and projected growth in storage requirements

Facility Infrastructure Assessment:

- Existing racking configuration and modification potential

- Aisle widths and vertical clearance measurements

- Floor condition and load-bearing capacity

- Electrical infrastructure for charging stations

- Temperature zones and transition frequency

Equipment Specification Criteria:

- Load capacity matching product weight profiles

- Lift height accommodating racking systems

- Aisle width compatibility with facility layout

- Battery technology aligned with operational hours

- Operator comfort features supporting shift requirements

Financial Analysis Components:

- Total cost of ownership over a 7-10 year equipment lifecycle

- Energy consumption comparison between battery technologies

- Maintenance cost projections based on utilization rates

- Productivity gains from operator comfort features

- Space optimization ROI from high-density equipment selection

UAE-Specific Considerations:

- Compliance with the Emirates Authority for Standardization requirements

- Parts availability and service response times in JAFZA and Dubai Industrial City

- Thermal cycling durability for extreme temperature transitions

- Humidity resistance during the summer months

- Vendor track record with pharmaceutical and food distribution clients

UAE food distributors, vitamin supplement companies, and pharmaceutical storage operators share common requirements: equipment reliability under thermal stress, compliance with product safety standards, and operational efficiency that preserves cold chain integrity. The intersection of these requirements points toward electric reach trucks with lithium-ion power systems for the majority of cold storage applications, with VNA forklifts serving large-scale facilities where space optimization justifies guidance infrastructure investment.

Selecting cold storage forklifts requires balancing technical specifications against operational realities. Equipment must perform reliably in demanding thermal environments while supporting productivity targets that determine distribution network effectiveness. For UAE facilities serving food safety and pharmaceutical applications, this decision carries implications extending beyond equipment costs to product integrity, regulatory compliance, and supply chain reliability.