Why Articulated Forklifts Are Becoming the Preferred Choice for Cold Storage Narrow Aisles

Cold storage is one of the most demanding environments in modern logistics, especially in facilities designed around Cold Storage Narrow Aisles, where space is limited and precision is critical. Temperatures are extreme, and operational costs rise with every additional minute a machine or operator spends inside a freezer room. As the global appetite for frozen foods, pharmaceuticals, and temperature-controlled goods continues to expand, warehouse operators face a pressing challenge: how to maximize capacity within Cold Storage Narrow Aisles without increasing footprint or driving up energy consumption.

This is why articulated forklifts have emerged as a transformative solution. Their exceptional maneuverability, narrow-aisle compatibility, and cold-environment engineering make them increasingly essential for high-density cold storage operations. They are no longer simply an alternative to traditional forklifts—they are becoming the preferred choice for premium facilities focused on efficiency and ROI.

The Demand for High-Density Cold Storage Is Surging

Cold chain logistics is in rapid expansion mode. Consumer behavior has shifted toward frozen foods, meal-kit subscriptions, and on-demand grocery delivery. Pharmaceutical requirements, including vaccines and temperature-sensitive biologics, have added new layers of pressure to the supply chain.

At the same time, cold storage real estate remains extremely costly. The cost per square meter can be 3–5 times higher than ambient environments due to insulation, refrigeration, and specialized construction. This makes density optimization the top strategic priority for operators.

For many facilities, transforming existing layouts is far more cost-effective than expansion. But retrofitting narrow aisles comes with challenges—especially for traditional forklifts. This is where articulated forklifts provide a competitive edge.

Why Cold Storage Environments Challenge Traditional Equipment

Operating inside sub-zero conditions introduces mechanical, spatial, and safety challenges that standard reach or counterbalance trucks cannot always solve effectively.

1. Temperature Affects Machine Performance

Low temperatures reduce battery output, thicken hydraulic fluids, and cause condensation that interferes with sensors and electronics. Traditional forklifts often lose speed or stability and require more frequent downtime.

2. Aisles Are Tight and Racking Heights Are Increasing

Cold rooms prioritize vertical storage. But Cold Storage Narrow Aisles and high lift heights limit maneuverability for conventional lift trucks, slowing down operations and increasing the risk of damage.

3. Efficiency Directly Impacts Energy Spend

Every second of activity inside the freezer raises energy consumption. Longer handling times, multiple maneuvers, and inefficient travel patterns drive up the refrigeration load.

These factors collectively highlight why equipment designed specifically for tight, frozen environments delivers significantly higher value.

Why Articulated Forklifts Are Ideal for Cold Storage Narrow Aisles

Articulated forklifts overcome the limitations of reach trucks and VNA (very narrow aisle) systems through superior geometry and precision control.

Exceptional Maneuverability in Small Spaces

The defining advantage is the 180° articulation of the mast, allowing operators to turn the mast independently of the chassis. This means:

- Direct, single-approach pallet entry

- Minimal reversing and repositioning

- Faster pick and put-away cycles

- Safer operation in reduced visibility

In tight freezer aisles, this level of agility is a game changer.

Operate in Ultra-Narrow Aisles Without Expensive Guidance Systems

Articulated forklifts can operate in aisles as narrow as 1.6–2.0 meters, rivaling VNA systems but without the need for:

- Wire guidance

- Rail guidance

- Special floor construction

- Dedicated VNA infrastructure

This immediately reduces warehouse redesign costs while increasing pallet density.

Cold-Optimized Engineering for Reliability

Modern articulated forklift models include features tailored for sub-zero environments such as:

- Low-temperature hydraulic oils

- Sealed electrical systems

- Anti-condensation heaters

- Reinforced drive motors

- Low-temp lithium-ion batteries

These enhancements ensure consistent lift speeds and reduced component wear—all critical for continuous cold storage operations.

Technology Enhancements Driving Performance in Cold Storage

Cold storage–ready articulated forklifts combine mechanical engineering with smart digital systems.

Low-Temperature Battery Technology

Lithium-ion powertrains maintain stronger performance in freezing conditions, offering:

- Faster charging

- Longer runtime

- Reduced capacity loss

- Minimal maintenance

A reliable battery is essential when every minute counts inside a freezer room.

Moisture and Frost Protection

Condensation can cause corrosion, short circuits, and reduced visibility. Cold-ready forklifts counter this using:

- Enclosed electronics

- Heated sensors

- Frost-resistant cabins

- High-intensity LED lights

These features reduce downtime and improve operator safety.

Advanced Telematics to Maximize Productivity

Real-time telematics are particularly valuable in high-cost environments like cold storage. They allow operators and managers to track:

- Performance inside frozen zones

- Battery health and charging cycles

- Impact events

- Operator productivity

- Travel routes and inefficiencies

This data helps optimize operating time and reduce unnecessary travel inside the freezer.

The Hidden ROI: Cost & Space Advantages That Drive Adoption

While performance matters, the real driver behind the adoption of articulated forklifts is the impressive financial impact they deliver.

Increase in Pallet Positions per Square Meter

By reducing aisle width requirements, articulated forklifts unlock substantial storage capacity gains. Many operators experience density improvements of 20–40% without major renovations.

Reduced Fleet Requirements

Because articulated forklifts combine the capabilities of reach trucks and counterbalance trucks, many warehouses can reduce fleet size and maintenance costs.

Lower Maintenance vs. VNA Systems

VNA trucks are highly specialized and expensive to maintain. Articulated forklifts offer similar or superior aisle performance but with simpler engineering and lower total cost of ownership.

Energy Efficiency Through Faster Cycle Times

Shorter operating time reduces refrigeration load and extends the life of freezer components.

This leads to measurable energy savings and lower operational costs.

Articulated Forklifts vs. Reach Trucks & VNA Trucks in Cold Storage

Aisle Size Requirements

- Articulated forklifts: 1.6–2.0m

- Reach trucks: 2.6–3.0m

- VNA trucks: Require dedicated guidance infrastructure

Productivity in Freezing Conditions

Articulated trucks maintain speed and stability thanks to cold-optimized hydraulics and motors.

Cost of Ownership

Compared to VNA, articulated forklifts offer:

- Lower maintenance

- Lower training costs

- No special floor or guidance systems

Operator Training & Ease of Use

Operators typically become proficient quickly due to intuitive steering and direct pallet approaches—an advantage in environments where staffing is tight.

Integrating Articulated Forklifts Into an Existing Cold Storage Facility

Deployment is straightforward, making them ideal for retrofits.

Aisle Adjustment & Racking Optimization

Facilities can immediately reclaim space simply by narrowing aisles to match articulated forklift capabilities.

Battery & Charging Strategy

Cold storage best practices include:

- Battery warm-up zones

- Strategic charging near freezer entry points

- Continuous monitoring via telematics

Safety & Precision Training

Operator confidence is key. Training emphasizes articulation control, visibility techniques, and safe maneuvering on icy floors.

Compliance & Cold Room Safety Measures

Articulated forklifts integrate easily into required protocols around PPE, environmental separation, and controlled access.

The Future: Automation & High-Density Cold Storage

As facilities push for even greater efficiency, articulated forklifts are evolving alongside broader warehouse technologies.

Semi-Autonomous Navigation

New models are incorporating automated aisle-following, obstacle detection, and guided putaway features.

AI-Based Fleet Optimization

Data-driven routing, predictive maintenance, and charge-cycle automation will drive multi-layered efficiency gains.

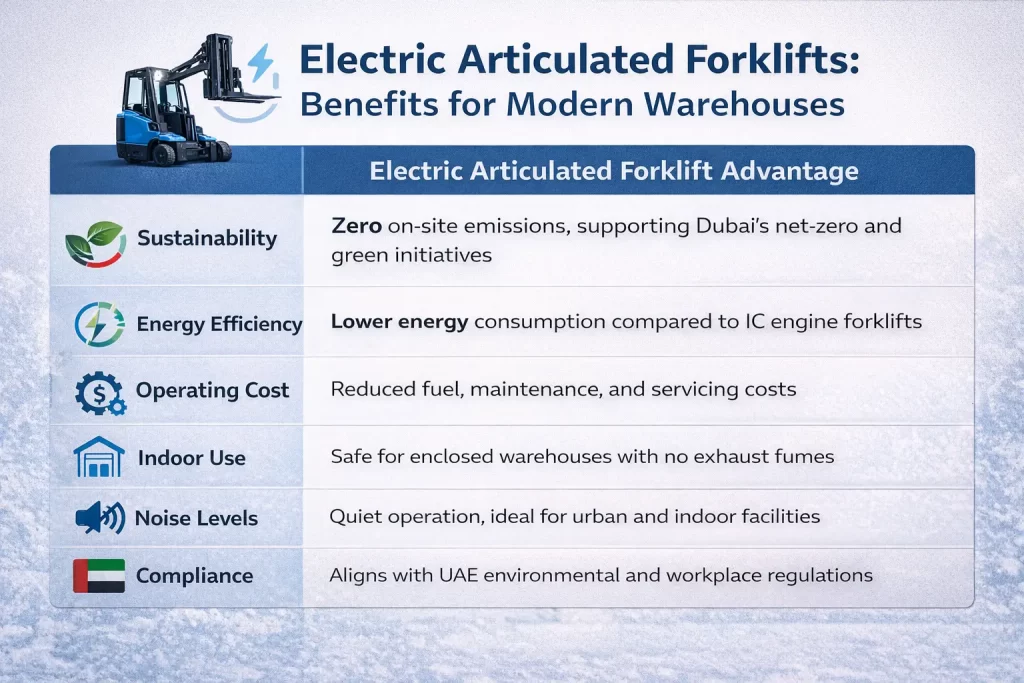

Sustainable Cold Chain Operations

Electric articulated forklifts align closely with global net-zero targets and the industry’s shift away from internal combustion equipment.

Final Thoughts

Cold storage operations demand equipment that can maximize space, maintain high productivity, and operate reliably in harsh environments. Articulated forklifts deliver all three—while reducing costs and improving long-term operational performance. Their Cold Storage Narrow Aisles capability, cold-environment engineering, and exceptional maneuverability make them the preferred choice for high-density facilities looking to modernize and scale efficiently.

As cold chain logistics continues to grow, articulated forklifts will play a pivotal role in shaping the next generation of temperature-controlled warehousing.