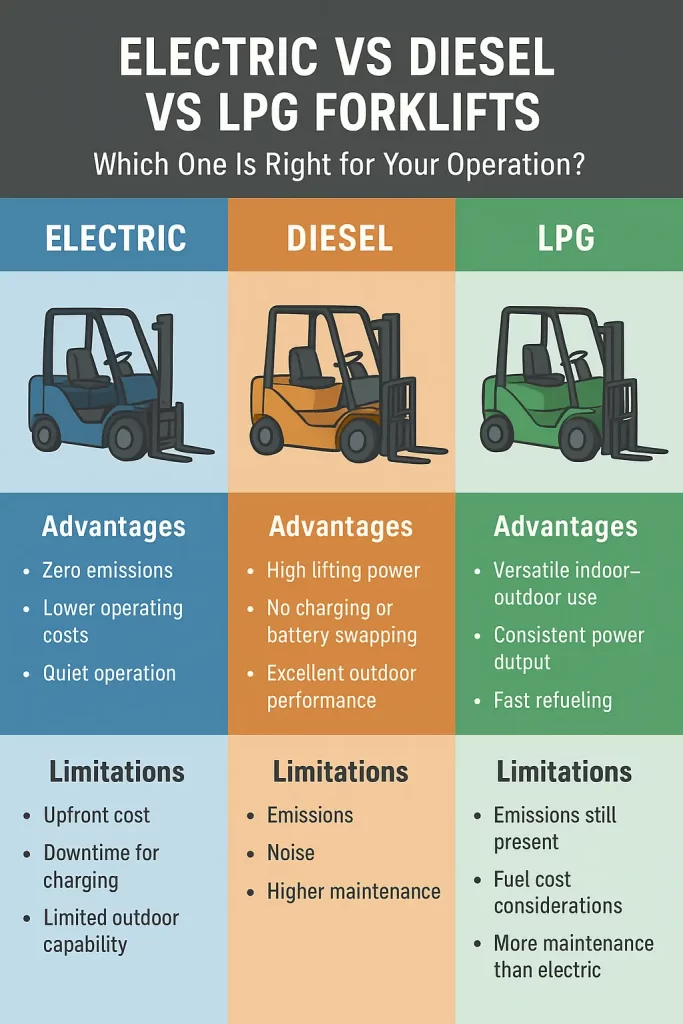

Choosing the right forklift for your warehouse automation, manufacturing facility, or outdoor yard is one of the most important operational decisions you can make. The right machine boosts productivity, cuts long-term costs, and enhances safety. The wrong choice, however, can lead to fuel inefficiencies, downtime, or performance limitations—especially if the forklift isn’t suited to your environment.

Among the most common forklift power options are Electric vs Diesel vs LPG Forklifts. Each type comes with clear advantages and trade-offs, and the best choice depends on your workload, environment, and long-term cost strategy.

This guide breaks down how each forklift type performs, where it excels, and which option makes the most sense for different operations.

Electric Forklifts: How They Perform and Where They Excel

Electric forklifts run on rechargeable battery systems—typically lead-acid or increasingly lithium-ion models. Over the last decade, they have become the preferred choice for many indoor operations due to efficiency, safety, and low noise.

Advantages of Electric Forklifts

1. Zero Emissions

Electric forklifts produce no exhaust fumes, making them ideal for indoor environments such as warehouses, food storage facilities, and pharmaceutical operations. This eliminates the need for ventilation systems required for fuel-burning forklifts.

2. Lower Operating Costs

Electric models have:

- Fewer moving parts

- Lower maintenance requirements (no oil, fuel system, or engine servicing)

- Stable energy costs compared to fluctuating fuel prices

Over the long term, this typically results in a lower cost of ownership.

3. Quiet Operation

Electric units run quietly, reducing noise pollution and improving operator comfort. This is especially beneficial for dense warehouse operations or multiple shifts.

4. High Precision and Smooth Handling

Electric forklifts deliver:

- Responsive acceleration

- Smooth operation

- Excellent maneuverability

These qualities are valuable in narrow aisles or high-accuracy lifting tasks.

Limitations of Electric Forklifts

1. Upfront Cost

The purchase price—especially with lithium-ion batteries—is higher than diesel or LPG options. However, lower lifetime costs can offset this.

2. Downtime for Charging

Lead-acid batteries require:

- Long charge times

- Cooling periods

- Dedicated charging spaces

Lithium-ion reduces this issue, but recharging logistics still matter.

3. Limited Outdoor Capability

Electric forklifts are generally less suitable for wet, uneven, or harsh outdoor environments.

Best Environments for Electric Forklifts

- Indoor warehouses

- Food, pharmaceutical, and clean environments

- Multi-shift operations with proper charging infrastructure

- Businesses seeking long-term cost efficiency and sustainability

Diesel Forklifts: Power, Durability, and Outdoor Performance

Diesel forklifts are known for raw power, long run times, and the ability to handle heavy-duty tasks in challenging conditions.

Advantages of Diesel Forklifts

1. High Lifting Power

Diesel engines produce strong torque, making them ideal for:

- Heavy loads

- Outdoor yards

- Construction sites

- Ports and forestry operations

For maximum lifting capacity, diesel remains the strongest option.

2. No Charging or Battery Swapping

Diesel forklifts refuel quickly and work continuously, making them reliable in operations where uptime is critical.

3. Excellent Outdoor Performance

Diesel units excel on:

- Rough terrain

- Uneven surfaces

- Long-distance runs

They remain reliable in outdoor weather conditions.

Limitations of Diesel Forklifts

1. Emissions

Diesel forklifts produce exhaust gases, making them unsuitable for indoor use without strong ventilation.

2. Noise

Diesel engines are significantly noisier, which can impact operator comfort.

3. Higher Maintenance

Diesel engines require regular maintenance such as:

- Oil changes

- Fuel system service

- Filter replacements

4. Fuel Costs Can Be Volatile

Diesel prices can fluctuate, affecting operating budgets.

Best Environments for Diesel Forklifts

- Outdoor material handling

- Heavy-duty lifting

- Construction, ports, and industrial yards

- Operations requiring long, continuous shifts

LPG Forklifts: Balanced Power for Mixed Environments

LPG forklifts operate on propane cylinders, offering a balance between the cleanliness of electric power and the strength of diesel.

Advantages of LPG Forklifts

1. Versatile Indoor–Outdoor Use

LPG units produce fewer emissions than diesel and can be used indoors with proper ventilation. They also perform well outdoors.

2. Consistent Power Output

Unlike electric models that may lose power as the battery drains, LPG engines deliver steady performance throughout the entire shift.

3. Fast Refueling

Changing LPG cylinders takes minutes, minimizing downtime.

4. Lower Upfront Cost

LPG forklifts typically cost less than electric models and have lower fuel system complexity than diesel engines.

Limitations of LPG Forklifts

1. Emissions Still Present

While cleaner than diesel, LPG units still produce exhaust and cannot be used in sensitive indoor environments such as food-production areas.

2. Fuel Cost Considerations

LPG cylinders must be replaced regularly, and costs vary by region.

3. More Maintenance Than Electric

LPG units still have engines, requiring:

- Spark plug replacements

- Oil changes

- Exhaust system maintenance

Best Environments for LPG Forklifts

- Mixed indoor/outdoor operations

- Businesses needing consistent power across shifts

- Facilities that cannot support battery-charging infrastructure

- Mid-range lifting and general warehouse use

Electric vs Diesel vs LPG Forklifts: Side-by-Side Comparison

| Feature | Electric | LPG | Diesel |

| Emissions | Zero | Low/Moderate | High |

| Noise Level | Very Low | Moderate | High |

| Indoor Use | Excellent | Good (ventilation needed) | Not recommended |

| Outdoor Use | Limited | Strong | Excellent |

| Lifting Power | Moderate | Moderate–High | Highest |

| Upfront Cost | High | Medium | Medium |

| Operating Cost | Low | Medium | High |

| Maintenance | Lowest | Medium | Highest |

| Refueling/Charging | Requires charging | Instant cylinder swap | Fast refuel |

Which Forklift Type Is Right for Your Operation: Electric vs Diesel vs LPG Forklifts?

Choosing the correct forklift depends on factors like workload, budget, space, and long-term planning. Here’s a comparison between Electric vs Diesel vs LPG Forklifts:

Choose Electric If…

- You operate primarily indoors

- Noise and air quality matter

- You want long-term savings

- You can support battery charging infrastructure

Choose LPG If…

- You need a forklift for both indoor and outdoor work

- You want continuous power throughout shifts

- You prefer fast refueling without charging stations

Choose Diesel If…

- Noise and emissions are not an issue

- Your operation is outdoors

- You handle very heavy loads

- You need maximum power and durability

Maintenance Standards From Major Manufacturers (Aras, Toyota, Hyster, Yale, Crown)

Leading global manufacturers use standardized testing and engineering benchmarks that influence forklift design and performance.

Key authoritative notes:

- Electric forklifts typically require 40–60% less scheduled maintenance because they have no engine oil, filters, or spark plugs.

- Diesel forklifts require more frequent service intervals due to engine wear, fuel injection systems, and emissions components.

- LPG forklifts require periodic inspections of fuel hoses, tanks, and regulators to meet safety guidelines.

OSHA Requirements for Forklift Use (U.S. Occupational Safety & Health Administration)

OSHA defines forklift safety under 29 CFR 1910.178, which includes specific guidance on emissions, indoor use, and fuel types.

Key authoritative points:

- Diesel and LPG forklifts must meet OSHA permissible exposure limits (PELs) for carbon monoxide when used indoors.

- OSHA states that electric forklifts are preferred for indoor environments because they produce zero exhaust emissions, reducing air-quality risk.

- Refueling (diesel/LPG) and recharging (electric) areas must follow OSHA’s fire-safety and ventilation requirements.

- Electric forklifts classified under “Type E, ES, EE, EX” must match the facility’s fire hazard classification.

Why this matters:

Including OSHA compliance shows your comparison is grounded in real industrial safety standards, not just product features.

EPA (Environmental Protection Agency) Emissions Standards

The U.S. EPA regulates emissions for nonroad engines, including forklift engines.

Key authoritative points:

- Diesel forklifts fall under EPA Tier 4 nonroad diesel engine standards, designed to reduce particulate matter (PM) and nitrogen oxides (NOx).

- LPG forklifts must meet EPA spark-ignition (SI) engine standards, which limit carbon monoxide and hydrocarbon emissions.

- Electric forklifts are classified as zero-emission vehicles, producing no on-site pollution.

Why this matters:

Environmental compliance is a top factor for companies with sustainability goals or indoor-air requirements.

ISO Safety Standards for Forklifts

The International Organization for Standardization (ISO) sets global performance and safety benchmarks.

Relevant ISO standards:

- ISO 3691-1: Industrial truck safety requirements

- ISO 5053: Classification of powered industrial trucks

- ISO 22915: Stability requirements

- ISO 15870: Safety signs

How they apply:

- Electric forklifts must comply with electrical safety and battery protection standards.

- Diesel and LPG trucks require compliance with exhaust-system safety, engine-heat protections, and fuel-system integrity.

- All forklift types must meet stability and braking requirements regardless of power source.

Final Thoughts

There is no single “best” forklift—only the best one for your environment between Electric vs Diesel vs LPG Forklifts. Electric forklifts lead in efficiency and indoor safety, LPG forklifts offer flexibility and consistent performance, and diesel forklifts remain unmatched for heavy-duty outdoor workloads. By understanding the strengths of each, your operation can choose the model that improves productivity, reduces costs, and keeps workers safe.