Warehouse operations sit at the core of modern supply chains. As order volumes grow, delivery expectations shorten, and labor markets tighten, businesses face a critical decision: continue with manual warehouse operations or invest in warehouse automation. While automation promises speed and efficiency, it also requires significant upfront investment. This article presents a clear, factual comparison of costs and return on investment (ROI) between warehouse automation and manual operations, enabling decision-makers to evaluate the most suitable approach for their business.

Understanding Manual Warehouse Operations

Manual warehouse operations rely primarily on human labor for tasks such as picking, packing, sorting, loading, and inventory management. Equipment like forklifts, pallet jacks, and shelving systems may be used, but core workflows depend on people rather than automated systems.

Cost Structure of Manual Operations

The main cost components of manual warehousing include:

- Labor wages and benefits

- Recruitment and training expenses

- Overtime and seasonal labor costs

- Human error-related costs, such as mispicks, returns, and rework

- Workplace safety costs, including insurance and injury-related downtime

While manual operations usually require lower initial capital investment, their ongoing operational expenses tend to increase over time. Labor costs typically rise annually, and scaling operations often means hiring more staff rather than improving efficiency per worker.

ROI Characteristics of Manual Warehouses

Return on investment in manual warehouses is generally slower and more limited. Productivity improvements depend heavily on workforce availability, training quality, and management oversight. Although manual operations can be flexible in the short term, long-term ROI may be constrained by labor shortages, higher turnover rates, and reduced consistency during peak demand periods.

What Is Warehouse Automation?

Warehouse automation involves using technology to perform or assist with warehouse tasks. This can range from basic automation, such as conveyor systems and barcode scanning, to more advanced solutions like automated storage and retrieval systems (AS/RS), robotics, and warehouse management software integrations.

Automation does not necessarily eliminate human labor; instead, it reduces dependency on repetitive manual tasks while reallocating workers to supervision, exception handling, and value-added activities.

Cost Comparison: Automation vs. Manual Operations Upfront Investment

Warehouse automation requires a higher initial capital investment. Costs may include:

- Automated equipment and machinery

- Software systems and integration

- Facility modifications

- Implementation and testing

In contrast, manual warehouses typically involve lower startup costs, focusing mainly on space, racking, and workforce hiring.

Operating Costs Over Time

Over the long term, automated warehouses often experience more predictable and stable operating costs. Automation reduces reliance on fluctuating labor markets and minimizes the financial impact of absenteeism, turnover, and overtime.

Manual warehouses, on the other hand, face ongoing cost variability. Labor expenses tend to rise, especially during peak seasons, and inefficiencies can compound as order volumes increase.

Productivity and Accuracy Impact on ROI

Automation generally improves throughput consistency and accuracy. Automated systems follow programmed workflows, reducing picking errors and minimizing delays caused by fatigue or human inconsistency. Higher accuracy directly affects ROI by lowering return rates, customer service costs, and inventory discrepancies.

Manual operations depend on individual performance, which can vary by shift, experience level, and workload. Even with training, manual environments are more prone to variability, which can negatively impact long-term ROI.

Scalability and Growth Considerations

Scalability is a major differentiator when comparing warehouse automation vs. manual operations.

- Automated warehouses scale by increasing system capacity or extending operational hours without proportional increases in labor.

- Manual warehouses scale primarily by hiring more workers, which can strain recruitment pipelines and increase overhead.

From an ROI perspective, automation supports growth without linear cost increases, while manual operations often see diminishing returns as scale increases.

Risk and Flexibility Analysis

Manual operations offer short-term flexibility, especially for businesses with unpredictable volumes or seasonal demand. It is often easier to reduce labor hours than to redeploy automated systems.

Automation introduces operational stability but requires careful planning. Poorly designed automation can lead to underutilized systems. However, when aligned with consistent volume and long-term demand, automation reduces operational risk tied to labor availability.

Measuring ROI in Real Terms

ROI in warehouse operations should not be measured by cost reduction alone. Key ROI indicators include:

- Cost per order processed

- Order accuracy rates

- Inventory visibility and control

- Throughput consistency

- Labor dependency reduction

Automation tends to improve multiple ROI metrics simultaneously, while manual operations may only optimize a few at a time.

Which Approach Delivers Better ROI?

There is no universal answer. Manual operations may deliver better ROI for small facilities, short-term projects, or low-volume environments where flexibility outweighs efficiency. Warehouse automation typically provides stronger ROI in medium to large operations with stable or growing order volumes and long-term operational goals.

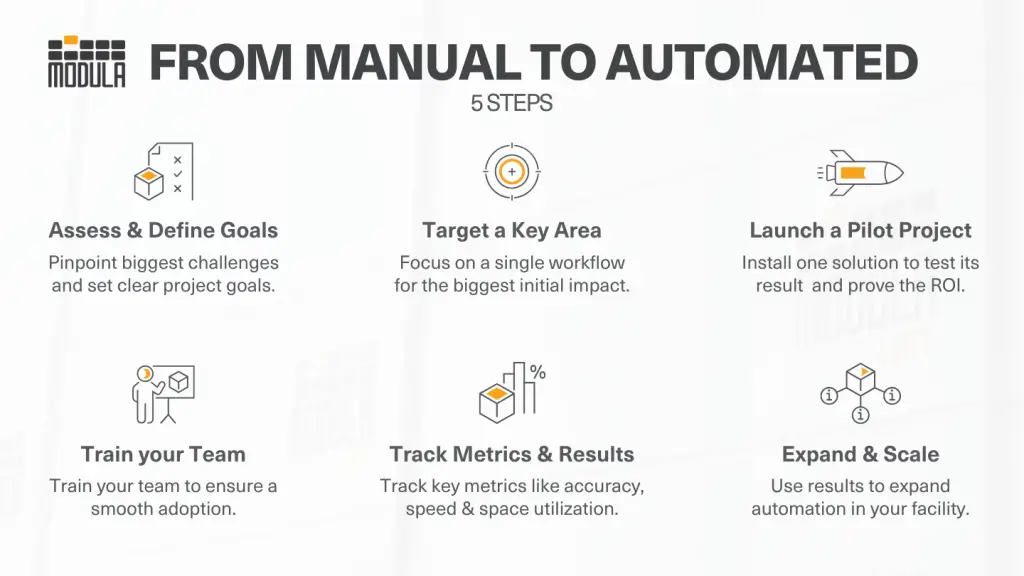

The most cost-effective strategy for many businesses is often a hybrid model, which combines targeted automation with human oversight to strike a balance between cost, flexibility, and performance.

Final Thoughts

The decision between warehouse automation and manual operations is ultimately a strategic one. While automation demands higher upfront costs, it often delivers stronger long-term ROI through efficiency, accuracy, and scalability. Manual operations remain viable for certain use cases but can become cost-intensive as complexity grows.

By evaluating true operational costs, growth expectations, and performance goals, businesses can choose a warehouse model that delivers sustainable returns without unnecessary risk.