🚀 Outcome, Lithium-Ion vs Lead-Acid Forklift Batteries—what you’ll gain from this blog

- A two-step formula to calculate pay-back in months for any forklift fleet.

- Fresh 2025 cost benchmarks in AED/kWh, cycle life, and maintenance hours ready to drop into your model.

- A side-by-side scorecard of productivity, safety, and sustainability factors that hide up to 40 % of the real expense.

- A five-question checklist to decide whether to upgrade, hybridize, or hold.

1 Why do three-shift warehouses feel the heat

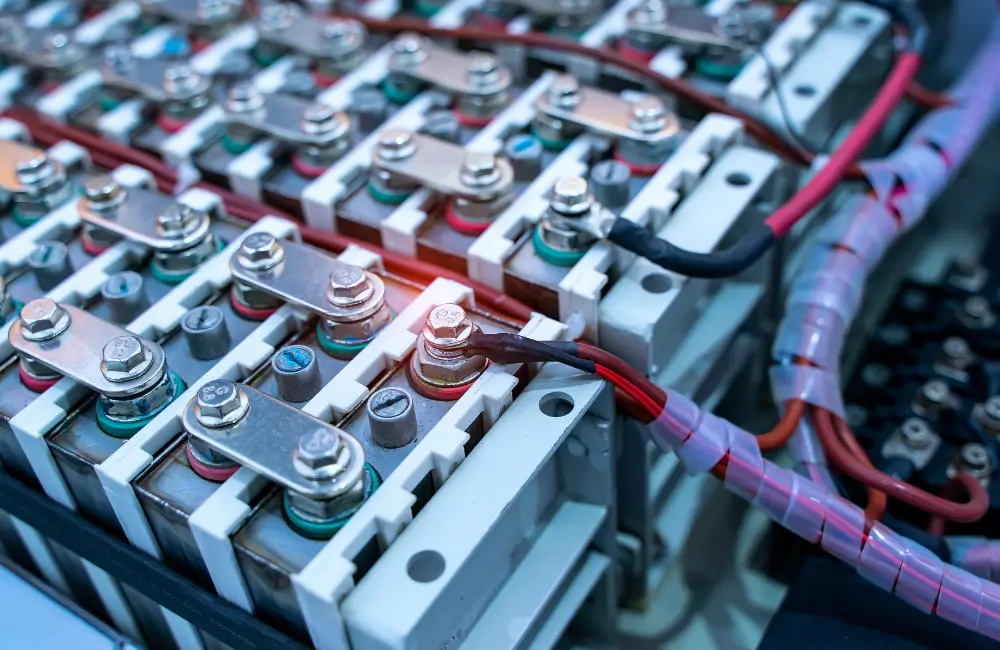

Running a forklift fleet non-stop means every minute of downtime snowballs into missed picks, overtime pay, and unhappy customers. Traditional lead-acid Forklift Batteries packs need eight hours to charge and another eight to cool, forcing you to keep two or even three batteries per truck. Lithium-ion flips that math with “opportunity charging”—fifteen-minute top-ups during breaks keep the same truck rolling through all three shifts.

Bottom line: the faster you cycle trucks, the wider the ROI gap grows.

2 Cost variables that move the ROI needle

| Cost Factor | Lead-Acid Forklift Batteries (2025) | Lithium-Ion Batteries (2025) | Why it matters |

| Pack price (installed) | AED 400–590 per kWh | AED 660–1,100 per kWh | Starting sticker price |

| Useful cycles | 1 500–1 800 | 4 000–5 000 | Determines replacement frequency |

| Daily maintenance | Watering + equalising | Wipe & go | Labour cost + downtime |

| Charge time | 8 h (plus cooling) | 1 h in bursts | Impacts fleet size |

Tip: Don’t forget the battery management system (BMS) bundled in most lithium packs; it adds upfront cost but slashes surprise failures.

3 Productivity gains that rarely show in the quote

- Opportunity charging boosts uptime 10 – 20 %. Top-up a total of one hour per shift and skip the battery-swap dance.

- One-battery-per-truck frees an entire dock bay or battery room—prime real estate for extra pallet positions.

- Voltage sag disappears. Lithium-ion delivers a flatter discharge curve, so the forklift lifts at full speed even at 20% state of charge—no creeping hydraulics, no operator frustration.

4 Safety & compliance: hidden money savers

Lead-acid Forklift Batteries charging demands drench showers, eyewash stations, and dedicated ventilation. Switching to lithium-ion instantly:

- Eliminates corrosive spills (no sulphuric acid).

- Removes hydrogen off-gassing, letting chargers sit on the warehouse floor.

- Cuts PPE spend and weekly watering labour.

Fewer compliance boxes mean fewer fines—and fewer line items on your material-handling budget.

5 The two-step ROI formula

Pay-back (months) = Δ CapEx ÷ Monthly Operating Savings

Step 1 – Δ CapEx

Price difference per battery × number of trucks.

Example: (AED 12 800 lithium – AED 8 100 lead-acid) × 10 trucks = AED 47 000 premium.

Step 2 – Monthly savings

Add:

- Energy (lithium is ~15 % more efficient).

- Maintenance labour (watering, cleaning).

- Spare batteries & swap equipment eliminated.

- Productivity gain (extra pallets per hour).

For a typical three-shift, 10-truck fleet the delta often hits AED 9 500–11 000 per month, driving pay-back inside 24–30 months.

6 Quick ROI snapshot (10-truck case)

- CapEx premium: AED 47 000

- Monthly Opex cut: AED 10 000

- Pay-back: ≈ 5 months faster than a two-battery lead-acid scenario

- Five-year net present value: ≈ AED 686 000 (at 8 % discount rate)

Swap in your local electricity tariff and wage rates to fine-tune.

7 Decision checklist

Ask these before you sign the PO:

- Duty profile: Does each forklift run more than five hours per shift? Heavy use accelerates pay-back.

- Electrical capacity: Do you have spare 480 V (or 400 V three-phase) to feed fast chargers?

- Ambient conditions: Sub-zero? Lithium still wins; lead-acid loses 30 % capacity below –20 °C.

- Sustainability targets: Lithium cuts Scope 1 emissions linked to diesel gensets.

- Financing options: Leasing or “power-by-the-hour” bundles shift CapEx to OpEx and can turn ROI positive from month one.

8 Frequently asked questions

Does lithium-ion work in older electric forklifts?

Yes—drop-in packs with CAN-bus adapters cover most major OEM models.

Will my operators need retraining?

Minimal. The biggest change is plugging in during breaks instead of swapping batteries.

What about fire risk?

Modern packs meet UL 2580 and IEC 62619; integrated BMS isolates faults long before thermal runaway.

Can I mix battery types?

Hybrid fleets are possible but watch for different charger footprints and safety rules—complexity may erode the ROI.

9 Conclusion: where the numbers land

If your forklift fleet runs more than two shifts daily, lithium-ion almost always pays for itself in under three years—and often in under two. Lower maintenance, higher uptime, and avoided compliance costs outweigh the sticker shock. For single-shift or low-utilisation sites, lead-acid forklift batteries can still be the thriftier choice—but run the two-step formula first.

Upgrade wisely, and your next forklift battery decision could unlock six-figure savings, shrink your carbon footprint, and reclaim warehouse space—all while keeping operators moving at full tilt.

Ready to crunch your own numbers? Download our free PDF and see exactly how fast lithium-ion drives profit for your powered industrial truck fleet.